high quality ah slurry pump manufacturers

Latest articles

There are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

high quality ah slurry pump manufacturers...

high quality ah slurry pump manufacturers 【high quality ah slurry pump manufacturers】

Read MoreMud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

high quality ah slurry pump manufacturers...

high quality ah slurry pump manufacturers 【high quality ah slurry pump manufacturers】

Read More>Slurry Pump VS Mud Pump

high quality ah slurry pump manufacturers...

high quality ah slurry pump manufacturers 【high quality ah slurry pump manufacturers】

Read MoreIf you want to know more information about the best slurry pumps wholesale, welcome to >contact us today or request a quote.

high quality ah slurry pump manufacturers...

high quality ah slurry pump manufacturers 【high quality ah slurry pump manufacturers】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

high quality ah slurry pump manufacturers...

high quality ah slurry pump manufacturers 【high quality ah slurry pump manufacturers】

Read MoreOther manufacturers looking for differentiation, if not the end result, may choose to add a small part to their pump assembly in the description, thus allowing in-line adjustment of the wear ring in the suction side lining assembly.

high quality ah slurry pump manufacturers...

high quality ah slurry pump manufacturers 【high quality ah slurry pump manufacturers】

Read MoreIn this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

high quality ah slurry pump manufacturers...

high quality ah slurry pump manufacturers 【high quality ah slurry pump manufacturers】

Read MoreFewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

high quality ah slurry pump manufacturers...

high quality ah slurry pump manufacturers 【high quality ah slurry pump manufacturers】

Read MoreIn addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

high quality ah slurry pump manufacturers...

high quality ah slurry pump manufacturers 【high quality ah slurry pump manufacturers】

Read MoreSlurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

high quality ah slurry pump manufacturers...

high quality ah slurry pump manufacturers 【high quality ah slurry pump manufacturers】

Read More

Popular articles

- Slurry pumps can also simply axially adjust the clearance between the impeller and the adjacent throat casing sealing surface. This helps to maintain pump performance when internal components begin to wear.

- What style of pump is suitable?

- Will solids size pass through the pump?

- >Slurry pump impeller is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

- reduce the discharge pressure of the pump to the lowest possible point, and.

- target=_blank>Slurry Pump

Latest articles

-

>Slurry Pump

-

Make sure you follow the basic rules of pump piping.

-

Slurry Pump

-

Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

-

When pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

-

Vertical Slurry Pumps Pump Sewage More Efficiently

Links

The Use of Double Needle Sewing Machines

Conclusion

1. Online Retailers Websites like Amazon or specialized sewing supply stores offer a vast range of options. You can easily compare prices and read reviews from other users.

Professional upholstery machines not only improve the quality of stitching but also significantly increase productivity. The ability to sew through thick materials quickly translates to shorter project turnaround times. For businesses that rely on fast production rates, investing in a professional machine can lead to better profit margins.

One of the key features of a woven sack sewing machine is its speed and efficiency. These machines are designed to work quickly and accurately, allowing for high volume production of woven sacks. This is essential for industries that require large quantities of sacks to package their goods for distribution.

woven sack sewing machine

In summary, twin needle sewing is an invaluable tool for any sewist looking to improve the quality and creativity of their projects. From creating professional hems to enhancing decorative elements on clothing, twin needles offer a wide array of applications that cater to both functional and aesthetic needs. As sewists continue to explore different techniques and challenges, mastering twin needle sewing can significantly broaden their capabilities and inspire new ideas. Whether for everyday wear, special projects, or creative crafts, the twin needle technique undoubtedly deserves a place in any sewing repertoire.

As technology continues to advance, the future of high-speed overlock sewing machines appears promising. Innovations such as computerized controls, integrated cutting systems, and enhanced automation are expected to further streamline the sewing process. The integration of sustainability practices, such as fabric-saving features and energy-efficient operations, will also likely gain traction as the industry shifts towards more environmentally friendly practices.

Heavy-duty sewing machines are specifically designed to handle thick fabrics and multiple layers with ease. Unlike standard sewing machines, they feature robust constructions, stronger motors, and specialized needles, making them ideal for tasks that require extra strength. Whether you are working with denim, upholstery, or quilts, a heavy-duty machine provides the reliability needed to ensure a smooth sewing experience.

What are Heavy Duty Sewing Machines Used For?

The double needle sewing machine can be particularly beneficial when working with fabrics such as denim, knits, and other stretch materials. It provides a more intricate finish compared to single needle machines, often used for hems, decorative stitching, and specific sewing techniques like topstitching.

Technological Advancements

A chain stitch sewing machine is designed to create a particular type of stitch known as a chain stitch. Unlike a standard straight stitch, which uses two threads (one for the upper and one for the lower), the chain stitch employs a single thread that passes through the fabric, forming a loop. This method results in a stitch that is both strong and flexible, making it ideal for various applications, including quilting, apparel manufacturing, and decorative sewing.

One notable aspect of climbing rope sewing machines is their ability to perform multiple stitching types. These include zigzag, straight, bar-tack, and backstitch, which provide additional reinforcement at critical stress points. The precision of the stitching is vital; a well-sewn climbing rope end can be the difference between safety and disaster for a climber. These machines also often come with adjustable speed controls to ensure that each stitch is executed with utmost care and accuracy, reflecting the high standards of quality required in the climbing industry.

Features of a Zigzag Presser Foot

gsc367 . They study a variety of genetic disorders, including both rare monogenic disorders and common complex disorders. They learn about the genetic basis of these disorders, how they are diagnosed and treated, and how genetic testing can be used to identify individuals at risk.

In conclusion, a sail making sewing machine is an essential tool for anyone involved in sail making or repair. With the right machine, you can create high-quality sails that will stand the test of time. Take the time to research and compare different options for sale to find the perfect sewing machine for your needs. Happy sewing!

Advantages of Using Two Needle Embroidery Machines

C. Handling Different Fabrics and Materials:

Here, we’ll provide tips on handling different types of fabrics, including denim, leather, canvas, and thick upholstery materials. We’ll discuss techniques such as adjusting stitch length and using appropriate presser foot attachments to achieve professional results.

Utilizing a twin needle can greatly expand your sewing capabilities, providing a professional touch to your garments and home projects. By selecting the right needle, preparing your machine, and mastering the various settings, you can achieve beautiful, durable results in no time. Happy sewing!

3. Better Grip and Control Thick threads, being more substantial, provide better grip during the sewing process. This is particularly beneficial for those who are new to leatherworking, as it offers added control when stitching. The increased thickness helps prevent the needle from slipping, allowing for more accurate, even stitches.

Conclusion

Furthermore, many hand sewing machines include a built-in walking foot, which helps to evenly feed multiple layers of fabric through the machine. This is essential in upholstery work to prevent slipping and misalignment, ensuring that the final product is both aesthetically pleasing and structurally sound.

Sustainability is another significant benefit of these machines. With the increasing awareness of environmental issues, the textile industry is under pressure to adopt more sustainable practices. Automatic template sewing machines contribute to this goal by enhancing fabric utilization. By accurately cutting fabric and minimizing waste, these machines help reduce the environmental footprint of textile production.

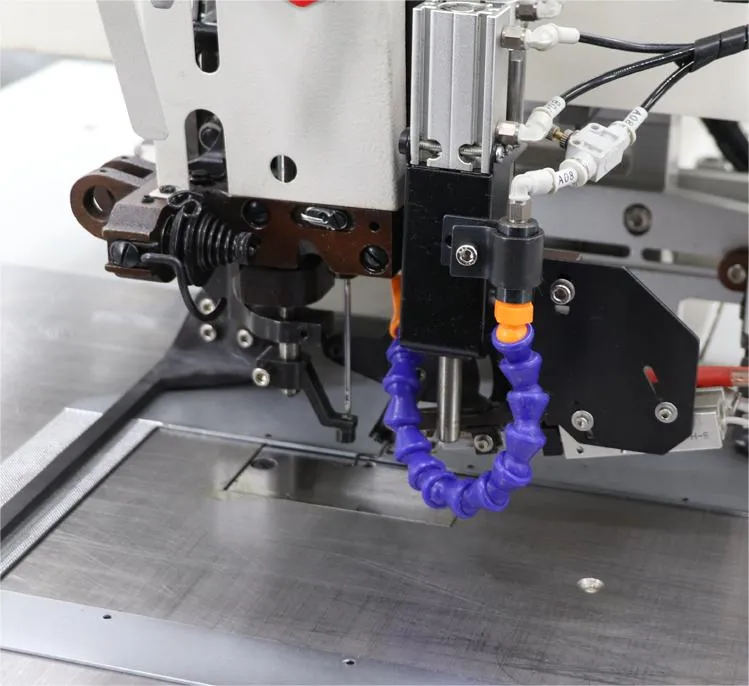

automatic template sewing machine

When searching for leather sewing machines for sale, there are several key features to consider

The intersection of technology and craftsmanship in the leather industry is not just a trend; it reflects the ongoing evolution of manufacturing processes in response to changing consumer demands. Industrial sewing machines designed for leather are pivotal in this transformation. By combining speed, efficiency, and precision, these machines not only enhance productivity for manufacturers but also contribute to the overall quality and durability of leather products in the market. As the industry continues to innovate, it is likely that we will see further advancements in sewing technology that will continue to elevate the art of leatherwork.

The hand-powered leather sewing machine is more than just a tool; it symbolizes a return to craftsmanship and traditional skills in a fast-paced world. With its ability to create high-quality, bespoke items, this machine continues to be an invaluable asset for leatherworkers. As artisans embrace the beauty of handmade products, the hand-powered leather sewing machine endures as a testament to the artistry and dedication that define the craft of leatherworking. Whether you are a seasoned artisan or a hobbyist, exploring the world of hand-powered sewing machines can elevate your leatherwork experience and enhance your creativity.